A simple solution for phosphorus removal

June 11, 2019

To reduce these effects the regulatory body is seeking lower consent values for phosphorous from treatment works, resulting in significant expenditure for water businesses throughout the UK. The resulting drive to find an efficient, cost-effective means of biological phosphorous removal is pushing development in this key aspect of waste water treatment. With few treatment works able to accept any process that requires significant land use, finding a solution that also has a compact footprint is the ultimate goal.

With the focus on new technology, it’s easy to overlook existing solutions, but one such does exist. For over thirty years the Austrian company, SFC Umwelttechnik, has been providing the technical expertise behind efficient and very compact Bio-P removal plants throughout the world. Most importantly, these have included installations in the UK and Ireland, so this established technology is already proven to work in the UK environment and is known to consistently meet the spot sampling approach used by the UK regulator. The plants, using an established process which SFC designate as ‘C-TECH’, can be considered as a specific and very efficient development of the well-known Sequencing Batch Reactor. The C-TECH system delivers all the required benefits (low operation and maintenance requirements, low energy consumption, low TOTEX cost, and compact footprint) without the risks associated with new technology solutions.

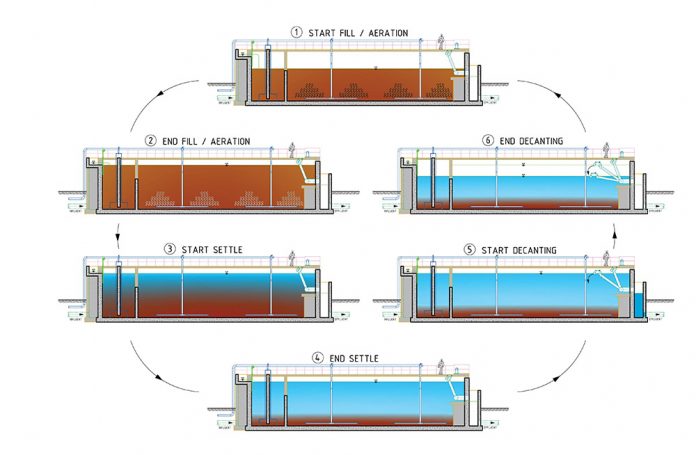

The C-TECH process involves a number of treatment basins operating in a staggered sequence to handle continuous incoming flows. Using multiple basins eliminates the need for an upstream balancing tank and also provides immediately available redundant capacity. This capacity allows one basin to be removed for inspection or maintenance when required without affecting plant throughput or discharge quality.

Each basin operates in the same way using a cycle of three distinct process phases. These are the fill/aerate phase, the settle phase and the decant phase. Incoming flows from the pre-treatment area of the Works pass, with no requirement for primary treatment, direct to the anaerobic selector area of the appropriate basin. Here the flows are joined by returned flow from the aeration area further along the basin. The conditions in the selector area stress the organisms and promote the development of ‘Macroflocs’, which are maintained throughout the full process cycle. These oversize flocs contain an external aerobic zone, an internal anoxic zone, and phosphorous accumulating organisms or PAOs. As a direct result of their make-up, simultaneous nitrification and denitrification occurs throughout the cycle. The PAOs operate to take up phosphorus from the surrounding bulk liquors, and they are periodically removed from the basin as part of the sludge removal process. The result is an effluent discharge with very low phosphorous content, typically <1mg/l with no chemical addition.

As well as providing consistently high standard effluent, the C-TECH process removes the need for land-hungry primary and final settlement tanks as well as tertiary treatment plant. Coupled with the compact size of a group of basins the full treatment process is provided within a small overall footprint, allowing release of land for other purposes, or scope for dealing with increased flows.

Operation and maintenance of the basins and related equipment is straightforward: each basin needs only one dissolved oxygen monitor and an ultrasonic level device to control the process. With no in-tank mixers, a simple decant assembly for effluent discharge and no complex analytical instrumentation to nursemaid, C-TECH provides high-tech Bio-P removal using the simplest of equipment.

By Paul M Roberts - Commissioning Manager